Hochleitfähiges 3,5-W-Wärmeleitfähiges Silikonpad zur Kühlung von Spaltfüllern für CPU-Premium-Isolierungselemente

TIF100-35-11UFWärmeleitfähige Schnittstellenmaterialien werden verwendet, um die Luftspalte zwischen den Heizelementen und den Wärmeableitungsrippen oder der Metallbasis zu füllen. Ihre Flexibilität und Elastizität machen sie geeignet, um sehr unebene Oberflächen zu beschichten. Wärme kann von den Heizelementen oder sogar der gesamten Leiterplatte auf das Metallgehäuse oder die Wärmeableitungsplatte übertragen werden, was die Effizienz und Lebensdauer der wärmeerzeugenden elektronischen Komponenten effektiv erhöht.

Merkmale:

> Gute Wärmeleitfähigkeit:3,5W/mK

> Natürliche Klebrigkeit, die keine weitere Klebstoffbeschichtung erfordert

> Hohe Konformität, passt sich an verschiedene Druckanwendungsumgebungen an

> Erhältlich in verschiedenen Dickenoptionen

Anwendungen

> Wärmeableitungsstruktur für Heizkörper

> Telekommunikationsausrüstung

> Automobilelektronik

> Batteriepacks für Elektrofahrzeuge

> LED-Fernseher und -Lampen

| Typische Eigenschaften von TIF®100-35-11UF-Serie |

| Farbe |

Grau |

Visuell |

| Konstruktion & Zusammensetzung |

Keramikgefülltes Silikonelastomer |

******* |

| Dichte |

3,0 g/cm³ |

ASTM D297 |

| Dickenbereich |

0,02~0,20 Zoll / 0,5~5,0 mmT |

ASTM C351 |

| Härte |

75 Shore 00 |

ASTM 2240 |

| Dielektrische Durchschlagspannung |

>5500 VAC |

ASTM D412 |

| Betriebstemperatur |

-40 ~200℃ |

******* |

| Dielektrizitätskonstante |

4,0 MHz |

ASTM D150 |

| Volumenwiderstand |

≥1,0X10¹² Ohm-Meter |

ASTM D257 |

| Brandverhalten |

94 V0 |

entspricht UL |

| Wärmeleitfähigkeit |

3,5 W/mK |

ASTM D5470 |

Produktspezifikationen

Standarddicke:

0,02 bis 0,20 (0,50 bis 5,00 mm) in Schritten von 0,01 (0,25 mm).

Standardgröße:

8"X16" (203 mm×406 mm).

Komponentencodes:

Verstärkungsgewebe: FG (Glasfaser).

Beschichtungsoptionen: NS1 (Nicht-Klebstoff-Behandlung). DC1 (einseitige Härtung).

Klebstoffoptionen: A1/A2 (einseitiger/doppelseitiger Klebstoff).

Hinweise: FG (Glasfaser) bietet erhöhte Festigkeit, geeignet für Materialien mit Dicken von 0,01 bis 0,02 Zoll (0,25 bis 0,50 mm).

Die TIF-Serie ist in kundenspezifischen Formen und verschiedenen Ausführungen erhältlich.

Für andere Dicken oder weitere Informationen kontaktieren Sie uns bitte.

Verpackungsdetails & Vorlaufzeit

Die Verpackung des Wärmeleitpads

1. mit PET-Folie oder Schaumstoff zum Schutz

2. Verwenden Sie eine Papierkarte, um jede Schicht zu trennen

3. Exportkarton innen und außen

4. Erfüllen Sie die Anforderungen der Kunden - kundenspezifisch

Vorlaufzeit: Menge (Stück): 5000

Geschätzte Zeit (Tage): Zu verhandeln

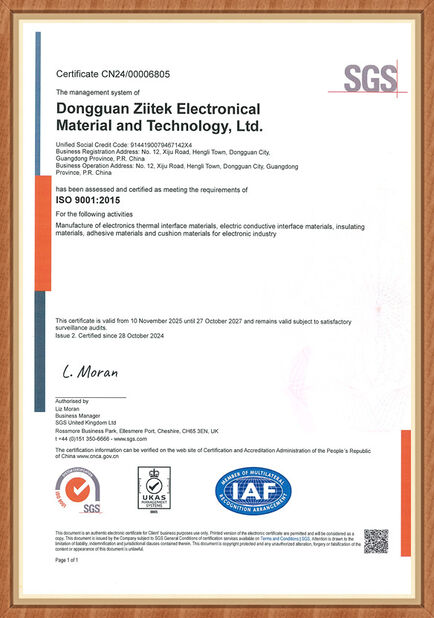

Firmenprofil

Ziitek Electronic Material und Technology Ltd. widmet sich der Entwicklung von thermischen Verbundlösungen und der Herstellung hochwertiger thermischer Schnittstellenmaterialien für den Wettbewerbsmarkt. Unsere umfassende Erfahrung ermöglicht es uns, unsere Kunden bestmöglich im Bereich der Wärmeentwicklung zu unterstützen. Wir bedienen Kunden mit kundenspezifischen Produkten, kompletten Produktlinien und flexibler Produktion, was uns zum besten und zuverlässigsten Partner für Sie macht. Lassen Sie uns Ihr Design perfekter machen!

Unsere Dienstleistungen

Online-Service: 12 Stunden, Anfragebeantwortung innerhalb kürzester Zeit.

Arbeitszeit: 8:00 bis 17:30 Uhr, Montag bis Samstag (UTC+8).

Gut ausgebildete und erfahrene Mitarbeiter beantworten alle Ihre Anfragen natürlich auf Englisch.

Standard-Exportkarton oder mit Kundeninformationen gekennzeichnet oder kundenspezifisch.

Kostenlose Muster bereitstellen

Kundendienst: Auch wenn unsere Produkte eine strenge Inspektion bestanden haben, zeigen Sie uns bitte den Nachweis, wenn Sie feststellen, dass die Teile nicht gut funktionieren.

Wir helfen Ihnen bei der Bearbeitung und geben Ihnen eine zufriedenstellende Lösung.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!